Products & Services

ACERALAVA manufactures long stainless steel products, specializing in Ingots, round and square bars and billets, rolled and forged (120-600 mm). Our steel shop facilities include EAF (Electric Arc Furnace) and AOD.

PROCESS DESCRIPTION

- In the melting shop: Starting from metals and scrap, steel is refined and chemistry is adjusted to be poured into different weight/size ingots.

- In the Forging and rolling mill: Ingots are either hot forged in two high capacity available press or rolled through a rolling reverse mill system.

- In the finishing lines Grinding is possible for Ingots Round and Square billets and for the round bars we have straightening, peeling and polishing lines.

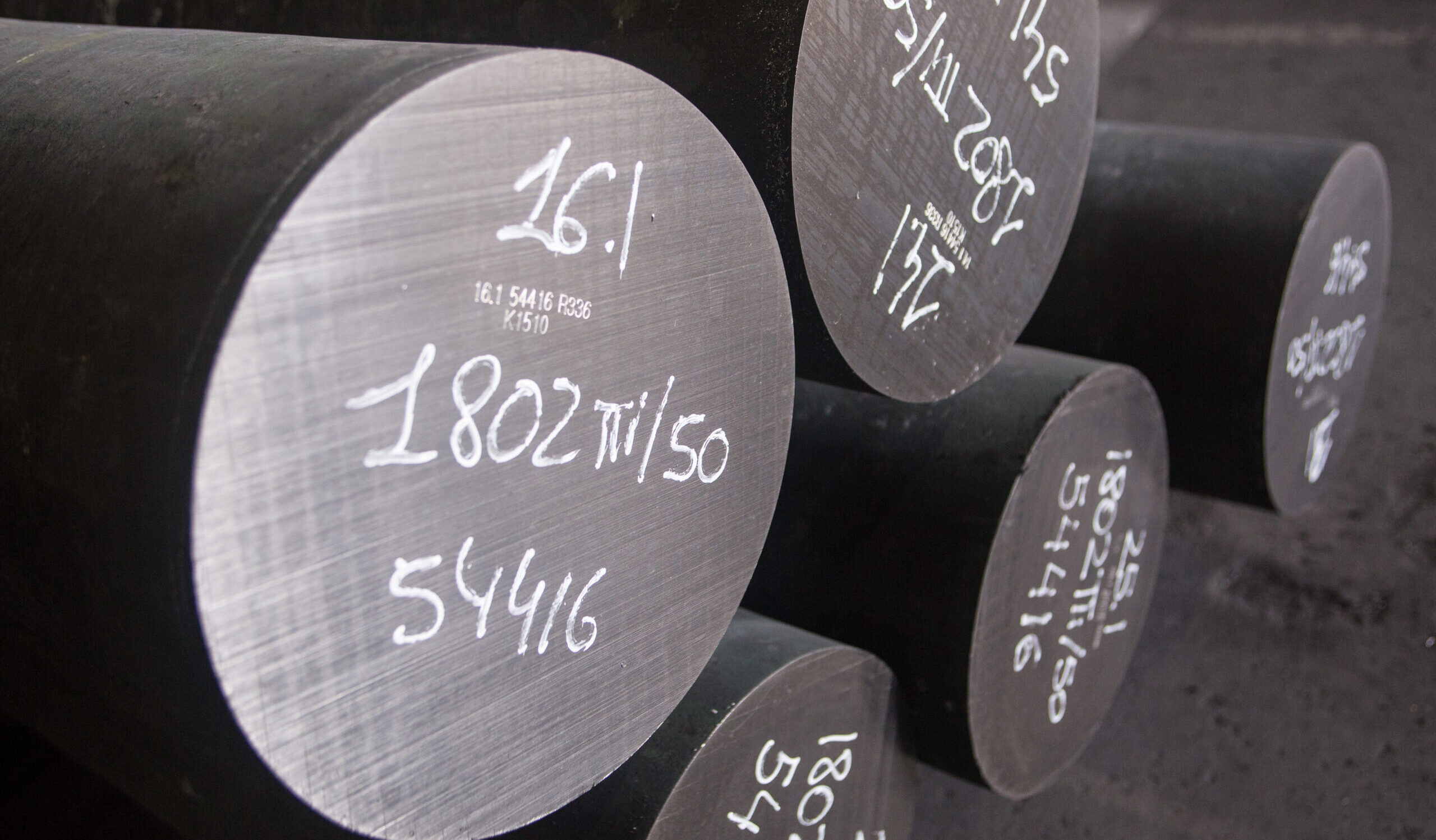

BARS

Aceralava supplies round bars with diameters ranging from 165 mm to 600 mm, as well as square bars from 120 mm up to 500 mm in diameter and 500 mm in width. Flat bars are available in sizes from 60 mm to 300 mm. Forged bars can be supplied in all required sizes, including round peeled bars in any grade, specification, approval, or surface finish condition. Flat bars help minimize the amount of material required and reduce machining time, improving productivity and generating cost savings. They are also easier to handle than large sections and thick plates, producing less scrap and resulting in lower overall costs.

BILLETS

Aceralava supplies round billets with diameters ranging from 165 mm to 600 mm, as well as square billets from 120 mm up to 500 mm in diameter and 500 mm in width. Flat bars are available in sizes from 60 mm to 300 mm, and forged billets can also be supplied. All billets offer good internal soundness and a high-quality surface finish, available in black, ground, or peeled conditions. The range of sizes is suitable for all types of downstream forged products. Flat billets used for hot-rolled flat bars are easy to handle, improve productivity, and provide significant cost savings.

INGOTS

Our Grades

At ACERALAVA, we offer a wide range of stainless steel grades and high-nickel alloys, manufactured in accordance with international standards (ASTM / EN). Our portfolio includes austenitic, ferritic, martensitic and duplex stainless steels, with carefully controlled chemical compositions to meet demanding industrial applications. Thanks to our expertise and flexibility, we provide the most suitable grade for each requirement, ensuring performance, reliability and consistency.