Products & Services

ACERALAVA manufactures long stainless steel products, specializing in Ingots, round and square bars and billets, rolled and forged (120-600 mm) [INCHES].

Product InformationSteel shop facilities include:

- EAF (Electric Arc Furnace)

- AOD

Process description:

- In the melting shop: Starting from metals and scrap, steel is refined and chemistry is adjusted to be poured into different weight/size ingots.

- In the Forging and rolling mill: Ingots are either hot forged in two high capacity available press or rolled through a rolling reverse mill system.

- In the finishing lines Grinding is possible for Ingots Round and Square billets and for the round bars we have straightening, peeling and polishing lines.

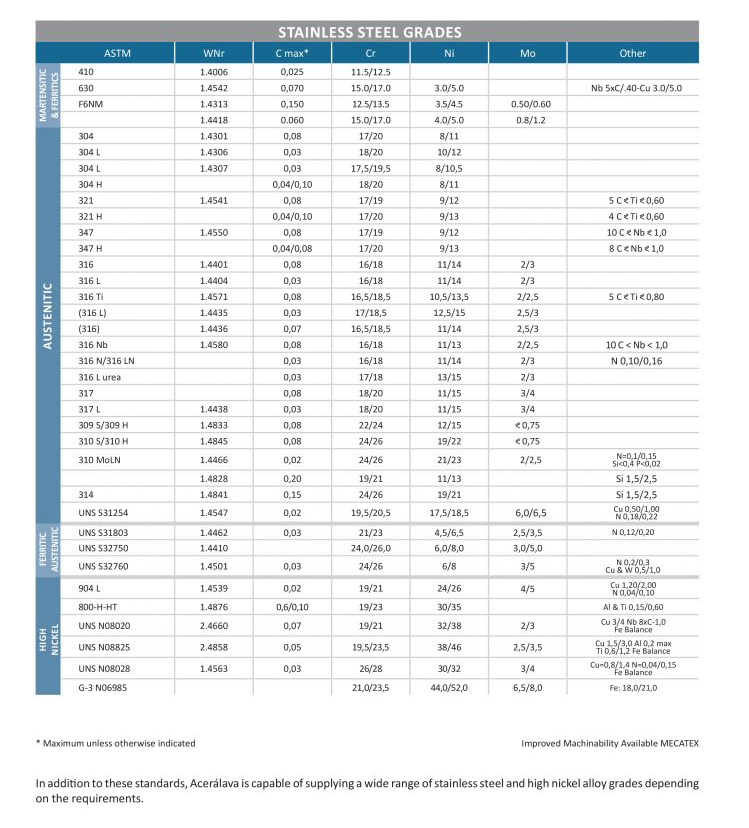

Our Grades

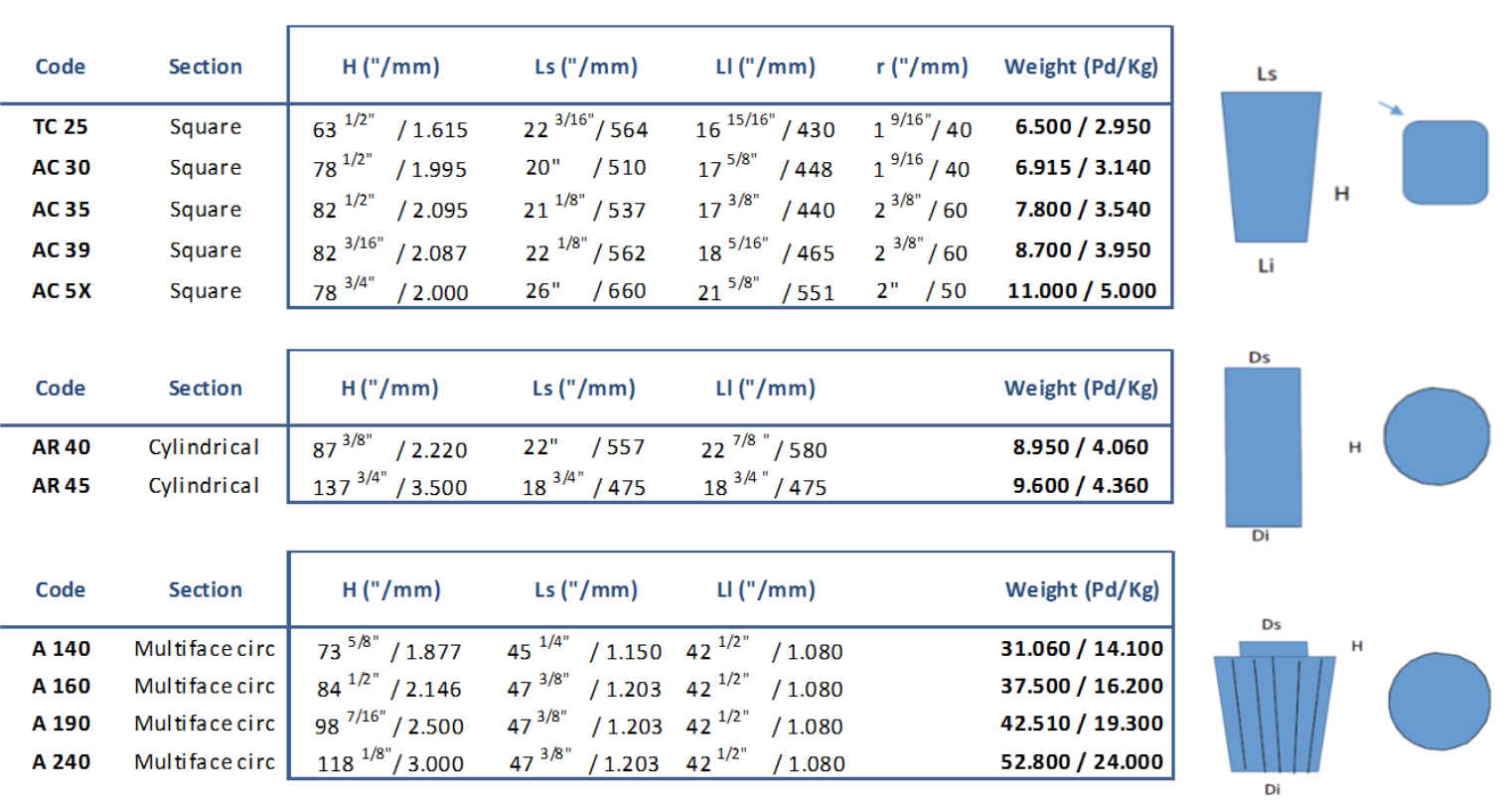

Our Ingots

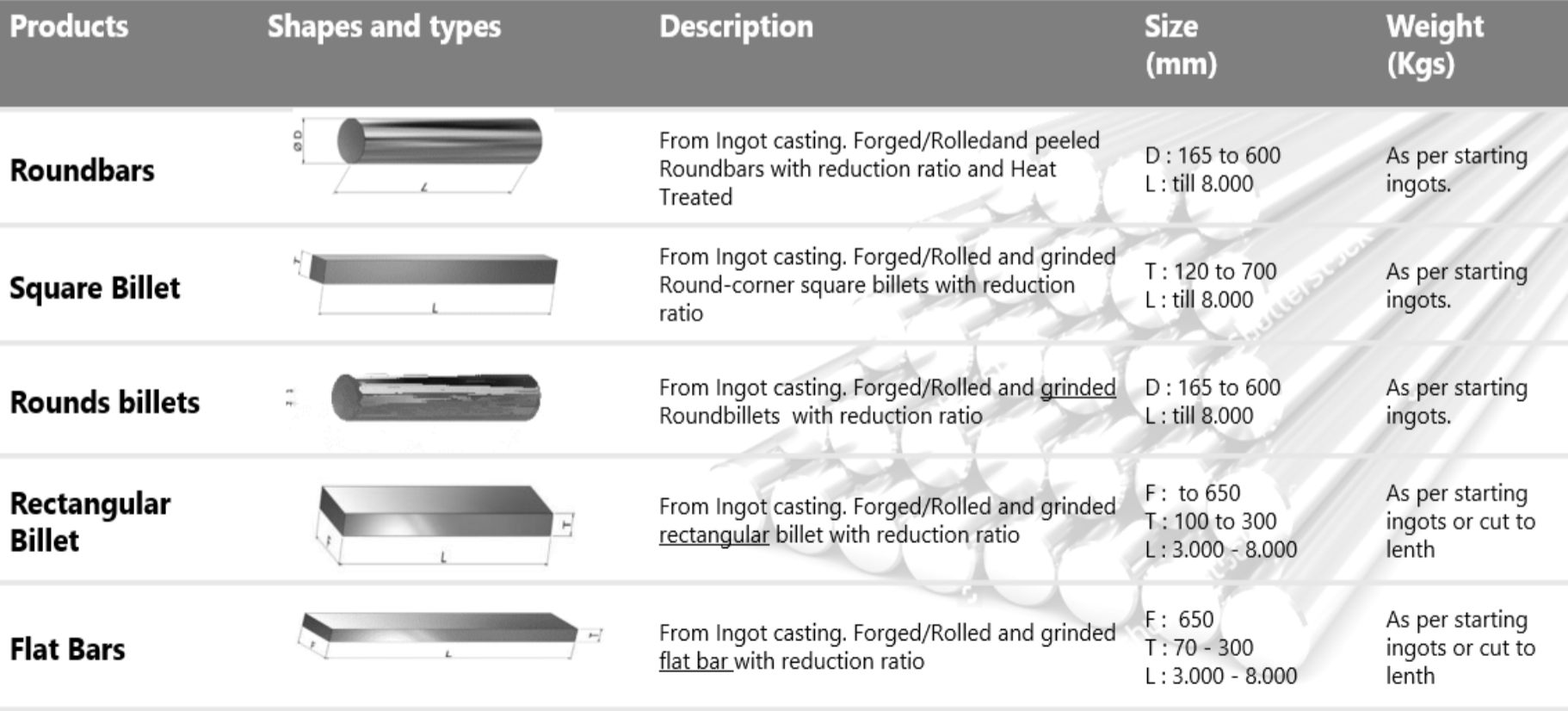

Our Billets / Bars

Aceralava has possibilities to make:

- Round billets and bars from 165 mm diameter to 600 mm

- Square billet and bars 120 mm diameter to 500 mm, and 500 mm width

- Flat bars from 60mm to 300mm

Benefits of our Bars & Billets

- Forged billets

- Good internal soundness, good surface finish either in black, ground or peeled conditions.

- Suitable sizes for all kind of downstream forged products.

- Flat billets for hot rolled flat bars, easy to handle, more productive and cost saving.

- Forged bars

- Suitable to all sizes, for round peeled bars, any grade, spec., approval or surface finish condition.

- Flat bar minimize material needed and machining time, improving productivity and cost saving.

- Easier to handle than big sizes and thick plates, less scrap produced, lower costs.