History

ACERALAVA (Acería de Álava, S.A.U.) was founded in 1975 as a wholly owned subsidiary of the TUBACEX Group, created to supply high-quality stainless-steel feedstock for the Group’s industrial operations.

From the melt shop onward, ACERALAVA manufactures ingots, billets and bars in stainless steels and high nickel alloys, supported by capabilities that include melting, forging and/or rolling, heat treatment and finishing operations. These products serve tube makers, forgers, re-rollers and machining shops worldwide.

TUBACEX is headquartered in Llodio (Álava), Spain, and operates an international industrial and service footprint to support customers in key markets.

We are a stainless steel melting shop and long-products manufacturer, serving demanding industries such as Oil & Gas, Energy and Nuclear. Today, backed by decades of experience, we produce high-quality stainless steel grades and nickel-based alloys, providing customers with reliable service and expert technical support.

Tubacex Group

Tubacex stands at the forefront of the global market in the design, manufacturing, and installation of complex industrial products and services with high added value, focusing primarily on the energy and mobility industries. The company specializes in advanced stainless steel, corrosion-resistant alloys (CRA), and precision machining services, delivering cutting-edge solutions for demanding applications. Committed to innovation and excellence, Tubacex operates through an integrated value chain, encompassing research and development, production, and final product delivery, ensuring superior quality and technological advancement.

MANUFACTURING PLANTS

COUNTRIES SUPPLIED

Operational Excellence

FAST TRACK DELIVERY CASE

During a critical maintenance repair at SHELL, ACERALAVA launched a fast-track program to deliver 120 tonnes of 20” forged round bars in just two weeks. A cross-functional, multi-department team monitored the project end-to-end and activated mitigation actions whenever any risk to the deadline was identified. A dedicated production route was implemented, and all testing samples and critical inspections were prioritized to ensure full compliance while meeting the committed delivery date.

NEW PRODUCT DEVELOPMENT

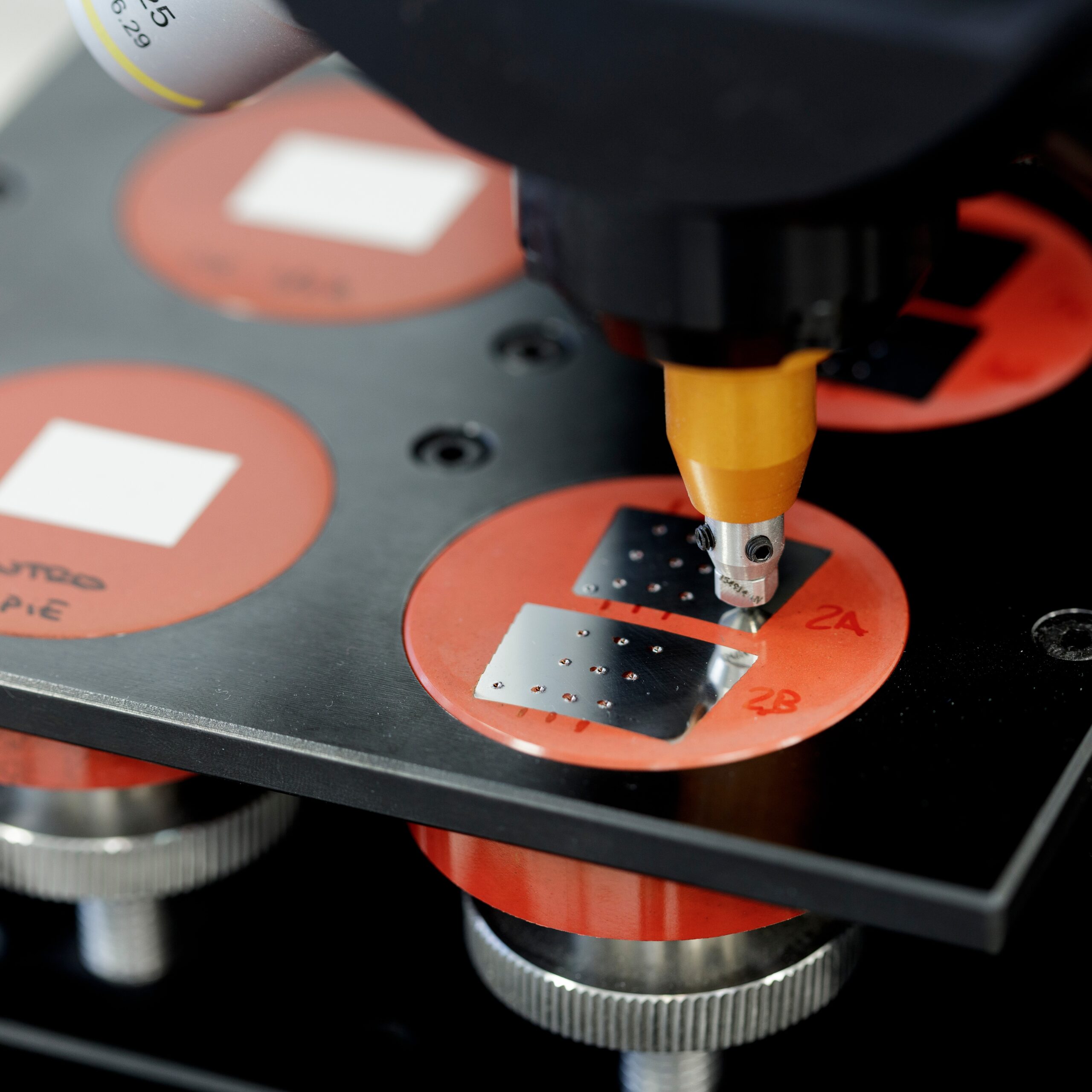

In close collaboration with a customer in the special constructions sector, ACERALAVA identified an opportunity to improve performance and manufacturability by developing a new product for a specific application. Based on the customer’s forging requirements and the machining of single-piece components, we designed and industrialized a tailor-made forged and rolled flat bar, optimized for the downstream process and the final part specifications.

VALUE ADDED ASSESSMENT

ACERALAVA carried out a Value Added Assessment in close collaboration with one of our key customers to review the end-to-end value chain, from ACERALAVA to the customer, and identify cost-optimization opportunities. A dedicated joint team mapped every step, from the scrapyard to the customer’s machining operations, challenging each activity across processing, transport and storage.

By eliminating inefficiencies and removing sources of loss, we implemented three improvement initiatives that delivered the cost reduction the customer needed to protect competitiveness and sustain their market-leading position.